Does the right commercial fryer really make a difference in an overloaded kitchen? Yes, it does. In a busy professional kitchen, the fryer is often the main engine of production; when it can’t keep up, the whole service slows down.

The right fryer doesn’t just cook food-it manages heat recovery, keeps texture consistent, and lowers the physical and mental strain on your team, turning a frantic “we’re in the weeds” rush into a smoother, more profitable service.

Running modern food service takes more than cooking skill; it also means understanding how equipment affects your costs and speed. Choosing the right model takes careful review of specs, often found in a detailed commercial deep fryer guide.

When you match the fryer’s technology to your menu, you remove one of the most common choke points on the line, so staff can focus on finishing plates instead of fighting a fryer that can’t hold temperature.

Why Commercial Kitchens Become Overloaded: The Root Causes

High-Volume Orders and Peak Hours

The main reason a kitchen reaches its breaking point is a sudden spike in orders during peak times. Whether it’s a Friday dinner rush or weekend brunch, the volume of tickets hitting the rail at once tests your capacity. When every few orders include fries or fried appetizers, the fryer becomes the busiest piece of equipment on the line.

If the fryer doesn’t have enough capacity or fast recovery, a “logjam” starts. It’s not just that food takes longer to cook-it’s the chain reaction. While one basket waits for the oil to heat back up, the next several orders are delayed, stretching ticket times for the whole menu, not just fried dishes. This domino effect is a clear sign of an overloaded kitchen.

Kitchen Layout, Workflow, and Equipment Bottlenecks

Sometimes overload isn’t about how many customers you have, but how your staff moves. A poor kitchen layout forces cooks to cross paths or work around obstacles to reach the fry station. If the fryer is stuck in a corner or too far from prep, a few seconds are lost on every batch. Over a shift, those seconds add up to many minutes of wasted labor.

Equipment bottlenecks also appear when the fryer’s output doesn’t match the rest of the line. If the grill can turn out thirty burgers in ten minutes but the fryer can only handle ten orders of fries in that time, the grill cook will keep waiting on fries. This mismatch in capacity creates constant friction and keeps stress levels high for the whole team.

Impact of Inadequate Frying Equipment on Service

A fryer that isn’t strong enough for the job leads to clear drops in food quality. Weak equipment usually struggles with “temperature recovery”-how long it takes the oil to return to the right cooking temperature after adding cold food.

When oil stays too cool, food soaks up more grease and comes out soggy and unappealing, which customers are more likely to send back.

Beyond poor results on the plate, weak equipment raises the risk of “dry firing” or overheating as it tries to keep up. This shortens the life of the fryer and creates safety hazards. A kitchen that is always fighting its tools is also a kitchen with low morale and high turnover, because staff feel they’re set up to fail every time the rush hits.

How the Right Commercial Fryer Improves a Busy Kitchen

Faster Cook Times and Higher Output

The right commercial fryer uses efficient burners or heating elements that give very fast recovery. As soon as one batch of wings comes out, the oil is almost ready for the next. This steady pace keeps food moving so no station on the line is stuck waiting.

High-output fryers often have larger oil vats or multiple tanks. This lets you cook different foods at the same time without flavors mixing. By increasing how much you can fry per batch, the kitchen can serve larger parties and turn tables more often, which boosts daily sales.

Improved Food Quality and Consistency

Consistency is what keeps guests coming back. People return because they expect the same crunch and flavor each visit. Modern, high-quality fryers use accurate thermostats and sensors to keep oil temperature within a tight range. This control helps avoid undercooked or over-browned food and keeps every batch at your standard.

Many newer fryers also move the oil more evenly, so there are no cooler “dead spots” in the vat. With even heat, food cooks uniformly. This level of control lets chefs fine-tune recipes, confident that the fryer will carry out the process the same way every time, no matter how busy it is.

Reducing Staff Workload and Stress

A dependable fryer acts like a steady partner for the crew. When it works predictably, the fry station becomes a manageable, routine part of the line. Features such as programmable timers and automatic basket lifts remove guesswork, so the cook can handle other tasks-like prepping the next ticket or finishing plates-without constantly worrying about burning food.

Simple operation and easy maintenance also lower the physical strain on staff. Many current models focus on better ergonomics and easier filtration, which means less heavy lifting and fewer messy cleanups. A smooth-running kitchen is a calmer kitchen, which leads to better communication, fewer mistakes, and a better workplace for everyone.

Which Commercial Fryer Fits Your Kitchen’s Demands?

Open-Pot Fryers: For Versatility and High Volume

Open-pot fryers are the industry workhorses. Their heating elements sit outside the tank or at the very bottom, leaving a wide-open vat that’s very easy to clean and scrape. They’re great for high-volume items that don’t shed much debris, such as frozen fries, hash browns, or cheese sticks.

Because most of the heat is near the bottom, these fryers excel with free-floating foods. They’re not as good for heavily breaded items, since crumbs fall directly onto hot surfaces, burn, and damage oil quality. For fast-food spots or busy bars that rely on frozen appetizers, the open-pot style is often the most efficient option.

Tube Fryers: Handling Heavily Battered Foods

Tube fryers have heating tubes that run through the middle of the oil. Below these tubes is a cooler zone, often called a “cold zone.” This feature is especially helpful for kitchens that cook fresh-breaded foods like fried chicken or fish. As batter and crumbs fall off, they sink into the cold zone, where they don’t burn and ruin the oil.

This layout helps oil last longer and keeps food from picking up a burnt taste from charred bits. Tube fryers can be a bit harder to clean because of the internal tubes, but their ability to handle heavy breading makes them very useful for Southern-style menus, seafood joints, and any spot known for scratch-made breaded dishes.

Flat-Bottom Fryers: Perfect for Delicate Foods

Flat-bottom fryers are specialty units used for foods that float and need gentle treatment, like tempura, funnel cakes, or classic doughnuts. These fryers have a shallow, flat vat with no tubes or cold zone. The whole area stays at a steady temperature, giving delicate items room to expand and cook evenly without getting trapped against equipment.

They usually heat from a plate underneath. While they’re excellent for light, delicate doughs, they aren’t suited for high-volume, crumb-heavy items, since there’s nowhere for debris to settle. They need frequent manual cleaning during service to keep oil in good shape, but for certain niche menus, they are the only way to get the exact results you want.

Pressure Fryers: Juicy Results for Chicken and More

Pressure fryers are a key tool for many fried chicken operations. They seal the cooking chamber and use steam pressure to cook at lower temperatures and faster speeds than open fryers. This holds in moisture and limits oil absorption, giving you meat that’s very juicy inside with a crisp exterior.

Because they cook so fast, pressure fryers are great for high-volume places that need to serve a lot of chicken or other proteins in a short time. They do need more careful safety training and maintenance because they are pressurized, but for busy chicken-focused concepts, their mix of speed and quality is hard to beat.

Ventless and Countertop Fryers: Space-Saving Solutions

Many kitchens don’t have a lot of floor space or a full hood system. Ventless fryers include built-in filters that clean grease and odors from the air, so you can use them in places where traditional hoods aren’t possible-like kiosks, c-stores, or older buildings. These self-contained units offer a “plug-and-play” way to add fried items without major construction.

Countertop fryers are smaller units that sit on tables or stands. They hold less than floor models, but they’re ideal for low-volume items or specialized uses, like a separate fryer for gluten-free or vegetarian foods. They let you expand your menu while saving floor and hood space.

Key Features to Look For in a Commercial Fryer

Automatic Temperature Control for Precise Cooking

During a rush, it’s easy to bump a manual dial or set it wrong. Automatic temperature control systems use digital probes to constantly track oil temperature. They adjust the heat on their own, making up for the drop when you add frozen food. This level of control keeps oil from getting too hot (which breaks it down) or too cool (which makes food greasy).

Many higher-end models also have “melt cycles” that gently heat solid shortening or cold oil so it doesn’t scorch. By handling these temperature changes automatically, the fryer takes care of the most technical part of frying, so even less-experienced cooks can get steady, professional results.

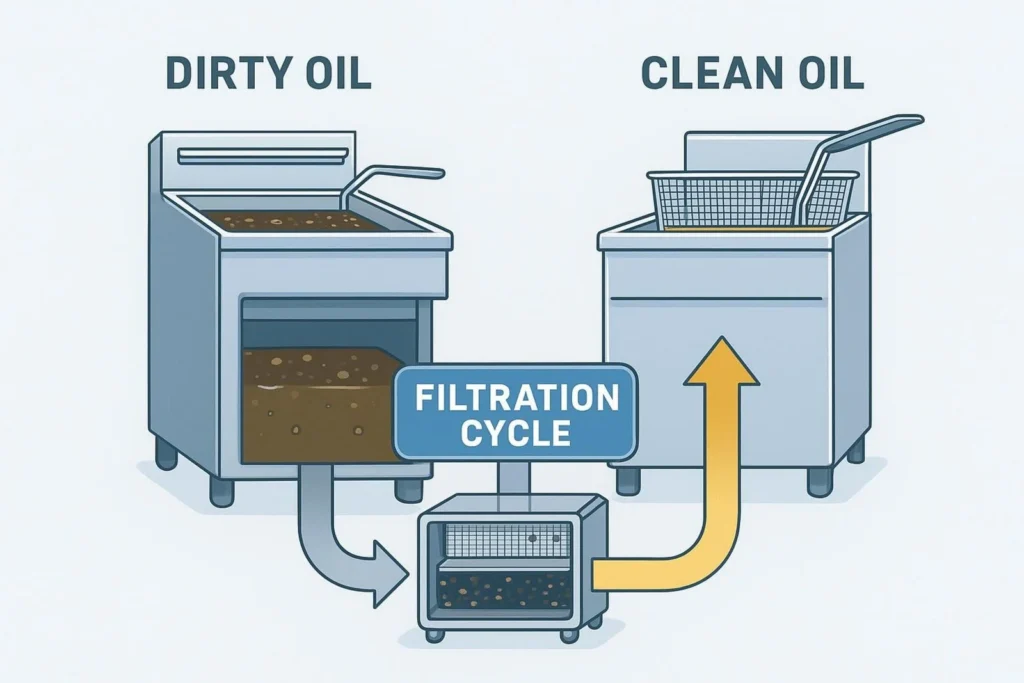

Built-in Oil Filtration and Cool Zone Technology

| Feature | Main Benefit |

| Built-in filtration | Longer oil life, better flavor, lower oil costs |

| Cool zone | Less burning of crumbs, slower oil breakdown |

Oil is one of the biggest ongoing costs in a kitchen. Built-in filtration lets staff filter oil several times a day with a button push. Removing food bits and burnt particles often lets you stretch oil life by up to 50%, saving a lot of money each year and keeping flavors clean.

Cool zone technology, like in tube fryers, is also very helpful. It gives crumbs a cooler area to rest away from the heat, which helps keep the oil’s smoke point from dropping too fast. Together, filtration and a cool zone are two of the most useful features for kitchens that want high quality while keeping operating costs under control.

Safety Shut-offs and Ease of Cleaning

Kitchen fires are a constant risk, and fryers cause many of them. Modern commercial fryers include high-limit safety shut-offs that cut power or gas if the oil gets too hot. This built-in protection helps keep staff and property safe. It’s also wise to choose units with cooler outer surfaces and secure, lockable drain valves to help prevent burns and spills.

Easy cleaning is another key point. If a fryer is hard to clean, it usually won’t be cleaned often enough. Look for features like rounded vat corners, removable basket hangers, and drain lines that are simple to reach. When cleaning is quick and simple, the fryer stays in better shape, works more reliably, and lasts longer.

Should You Choose Gas or Electric for Your Fryer?

Comparing Gas, Electric, and Propane Fryers

The choice between gas and electric often depends on what utilities your building already has. Gas fryers (natural gas or propane) heat up quickly and recover fast. They use burners to heat the oil through tubes or against the vat walls. They’re usually the go-to choice in high-volume kitchens where fryers run most of the day.

Electric fryers use elements directly in the oil, which makes them very energy-efficient because most of the heat goes straight into the oil. They may take a bit longer to heat up, but they offer very steady temperatures. Propane works well for food trucks or rural areas without natural gas lines and offers similar power to natural gas fryers.

Cost, Installation, and Utility Considerations

Install costs can vary a lot. A gas fryer needs a licensed gas hookup and must sit under a strong ventilation hood. If your kitchen doesn’t already have gas, adding lines can be costly. Electric fryers need high-voltage power (often 208V or 240V). They usually also need a hood, though some ventless electric models are more flexible about placement.

Example Electrical Spec: 208V / 3-Phase / 45 Amps

Operating costs depend on local utility rates. In some areas, natural gas is much cheaper than electricity, making gas fryers cheaper to run, even though they may need more burner and pilot-light maintenance. You should look at the “total cost of ownership,” including install, monthly utilities, and likely repair costs over the fryer’s life.

How Energy Efficiency Impacts Your Bottom Line

Energy-efficient fryers, such as models with Energy Star labels, can cut hundreds of dollars a year from utility bills. These units have better insulation, smarter heat exchangers, and advanced burners that use less energy when idling. In overloaded kitchens where fryers run hard, even a 10% efficiency gain can lead to big savings over time.

Many utility companies also offer rebates for buying energy-efficient commercial equipment. By choosing a higher-efficiency model, you lower your daily costs and may offset part of the purchase price with those incentives. In a business with tight margins, managing energy use is a strong way to protect profits.

Fryer Size and Capacity: Matching Output to Demand

Determining the Right Fryer Size for Your Menu

Fryer size is measured by oil capacity, usually from 15 to 100 pounds. To pick the right size, you need to look closely at your menu and your peak volume. As a rule of thumb, a fryer can cook about twice its oil capacity in food per hour.

(Pounds of food per hour) ≈ (Pounds of oil capacity) x 2

So a 40-pound fryer can produce about 80 pounds of fries in an hour. If you need 120 pounds in your busiest hour, a single 40-pound fryer will leave you behind.

You also need to think about the type of food. Dense items like frozen chicken breasts cook slower and drop oil temperature more than thin fries. If your menu is heavy on proteins, you may need a larger vat or more powerful heat (higher BTUs for gas or kilowatts for electric) than a kitchen that mostly serves light appetizers. Matching power to product is key to avoiding bottlenecks.

Gas Fryer Power Example: 120,000 BTU/hr

Electric Fryer Power Example: 17 kW

Space Limitations and Hood Requirements

Before you buy the biggest fryer you can find, measure your line space carefully. Many commercial kitchens are tight, and hood space is precious. You need to confirm that the fryer fits under your existing fire-suppression system and that staff have enough room to handle baskets safely. Also plan space for a dump station or landing area for finished food.

Ventilation is a must for safety. Most local codes require fryers under a Type I hood built to handle grease vapors. Extending a hood line can sometimes cost more than the fryer itself, so planning your equipment layout with your fire code and inspector’s rules in mind from the start is very important.

Planning for Future Growth and Scalability

A common mistake is buying based only on current traffic instead of future growth. If your brand is growing, an undersized fryer will turn into a major bottleneck fast. It’s often smarter to invest in a “battery” of multiple fryers lined up together. You can keep one or two running during slower periods and bring more online as business increases. To ensure your expanding kitchen remains profitable, visiting https://savefryoil.com/ can provide insights on how to extend fry-oil life and enhance food quality even as your volume scales.

Modular setups are very helpful for growth. You might start with two fryers and leave room in the hood for a third. This approach keeps your starting costs lower while still giving you a clear path to expand your capacity later without rebuilding the entire cook line.

What Accessories and Tools Optimize Fryer Performance?

Fryer Baskets, Skimmers, and Oil Filtration Systems

The right accessories can greatly improve your fry station. Good baskets with heat-resistant, comfortable handles reduce fatigue and burn risk. Using different basket sizes-like twin baskets for small orders and full baskets for big batches-helps staff use vat space more efficiently. Skimmers let staff remove floating debris between batches and help prevent burnt bits.

If your fryer doesn’t have built-in filtration, portable oil filtration units can help. These roll up to the fryer, pull out the oil, pass it through filters, and pump it back. This can give older fryers a big upgrade. Using quality filter media or powder can also remove fine particles and odors that basic filters may miss, helping your oil stay “sweet” longer.

Built-In and Aftermarket Safety Accessories

Safety add-ons are important in any busy kitchen. Splash guards are helpful if the fryer sits next to a grill or range, since they stop water or grease from jumping between stations and causing flare-ups. Crumb screens at the bottom of the vat catch larger bits, speed up end-of-shift cleaning, and protect the drain valve.

For high-volume spots, automatic basket lifts are very useful. They raise baskets out of the oil when the timer ends, even if the cook is momentarily distracted. This helps prevent overcooking, cuts waste, and keeps results more consistent.

Best Practices for Maintaining Your Commercial Fryer

Daily Cleaning and Preventive Maintenance

A steady daily cleaning routine is the best way to protect your fryer investment. At the end of each night, drain the fryer and scrub the vat to remove sticky, amber-colored buildup. This layer acts like insulation, makes the fryer work harder, and can eventually lead to breakdowns.

Preventive maintenance also means checking pilots, burners, and thermostats regularly. For gas units, keeping the air-to-gas mix correct avoids soot and keeps heat output strong. A quick weekly check of power cords and gas hoses for cracks or wear can help you avoid major failures during your busiest times.

Oil Filtration, Replacement, and Management

Oil management is both a flavor issue and a money issue. In most busy kitchens, oil is filtered at least twice a day-after lunch and at close. Test strips that measure Total Polar Materials (TPM) help you know when oil is worn out and must be replaced.

Example TPM Test Result:

– Reading: >24%

– Action: Oil must be replaced

Old oil doesn’t just taste bad; it actually slows cooking because it transfers heat less effectively.

To get the most life from your oil, cover fryers when they’re off to limit exposure to air and light. Train staff to shake off extra ice from frozen foods and avoid salting over the fryer, since salt quickly damages oil. These simple habits, along with regular filtration, can save a high-volume kitchen thousands of dollars a year.

Extending Fryer Lifespan and Reducing Repairs

A well-cared-for commercial fryer usually lasts 7 to 10 years. To reach the upper end of that range, you should do a “boil-out” on a routine basis-often once a week or when changing oil. During a boil-out, you fill the vat with water and a cleaning solution, then bring it to a simmer to strip away deep grease and carbon. This keeps heat-transfer surfaces clean and efficient.

Small problems, like slow heating or temperature swings, should be handled early. If you notice longer heat-up times or big temp changes, call a technician right away. Replacing a weak element before it fails completely is far cheaper than fixing a cracked vat or ruined control board. Treat the fryer well, and it will reliably support your kitchen for many years.

Frequently Asked Questions about Commercial Fryers in Busy Kitchens

Should You Upgrade Now or Wait?

If your current fryer breaks often, can’t hold temperature during rushes, or causes constant complaints about greasy or inconsistent food, you should upgrade now. Lost sales, wasted oil, and extra labor often cost more than a monthly payment on a new, efficient fryer. If your unit is more than eight years old, you’re likely missing out on newer energy-saving and oil-saving features.

Your menu also matters. If you’ve added more fried dishes or moved from frozen to fresh-breaded products, your old open-pot fryer may no longer be the right match. Moving to a tube-style or high-recovery model can solve overload problems almost overnight, letting your staff work faster and your guests enjoy better food.

How Often Should Fryer Oil Be Changed?

There is no single schedule that fits every kitchen; it depends on your volume and what you cook. Many busy kitchens change oil every 3 to 7 days. You should change it right away if the oil smokes at normal temperatures, looks very dark and foamy, or if food tastes bitter, burnt, or fishy. Oil test kits give the clearest answer and help you avoid throwing out good oil or serving food cooked in bad oil.

Regular filtration is the biggest factor in how long oil lasts. A kitchen that filters three times a day might get a full week from a vat of oil, while a kitchen that rarely filters may need to dump it after only two days. A strict oil management plan will help you find the right balance between quality and cost.

What Safety Training Is Required for Fryer Operators?

Safety training for fryer use should be part of every staff member’s onboarding. All operators should know how to light pilots on gas units, how to drain hot oil safely, and how to use the filtration system. They must also learn never to drop in frozen food loaded with ice, since that can cause dangerous boil-overs. Every staff member should know where the fire extinguisher and gas shut-off are located.

Training should also cover personal protective equipment (PPE) for cleaning and filtering, such as high-heat gloves, aprons, and face shields. Hot oil burns are among the most serious injuries in restaurants. A trained team works faster and is far less likely to face serious accidents during a rush.

Making the Decision: How the Right Fryer Changes Overloaded Kitchens

The move from an overloaded kitchen to a high-performing one often starts with one key upgrade. When you replace a weak, undersized fryer with a modern, efficient unit, the main bottleneck disappears. Orders that once took fifteen minutes now leave the pass in seven. The constant feeling of being “in the weeds” fades, and the mood in the kitchen shifts from panic to confident execution. This change in mindset is one of the most powerful benefits of good equipment; a confident team is a productive team.

Beyond faster tickets and better morale, the right fryer also protects your brand. In an age where a single complaint about soggy fries can spread quickly online, the steady quality that comes from accurate temperature control and good filtration is extremely valuable. As kitchen technology keeps moving forward-with smart fryers tracking oil life, usage, and energy-the gap between “good enough” and “excellent” grows wider. Choosing the right fryer now helps make sure your kitchen is ready for what tomorrow’s guests expect.